We are currently building some high quality Stereo 400w valve amplifiers from scratch, based on a GEC design of the 1950s with an updated input/driver stage, this revised input/driver stage allows more gain to be achieved with less stages of amplification, which in turn insures better closed loop stability than the original design.

When building high power valve amplifiers, using multiple KT88 output valves in push pull is preferable to using 2 very large valves, as an HT power supply requirement of 560v is very easy to achieve and output valve failure will not cause the amplifier to shut down, as at least 2 valves would have to fail in each half of the push pull output stage to even cause a loss in maximum output power, in fact the amplifier could still achieve 100w per channel with just 2 valves working each side.

The amplifiers are being built for the PA Market and fixed installations as valve amplifiers of this power - 400+400 w offering very low distortion are simply not available.

DC Heater supplies will be used throughout eliminating mains hum.

INPUT STAGE

We are experimenting with a Cascode differential pair input stage with constant current source and direct coupled cathode followers.

Using an ECC83 for the upper pair and an E88CC for the lower pair of the Cascode, this configuration should provide us with sufficient gain, we need to get the maximum possible gain with the minimum of gain stages, stability needs to be taken seriously when applying overall negative feed back to the amplifier.

OUTPUT STAGE

We are utilizing 10 KT88 beam-tetrode power valves in each output stage, coupled to an ultra linear output transformer, this will ensure a long service life as each output valve will be working @ 80w per device against a maximum for the KT88 of 100w. it would be possible to achieve 500w RMS plus, but reliability has to be a consideration and operating valves at the absolute limit is not a good idea.

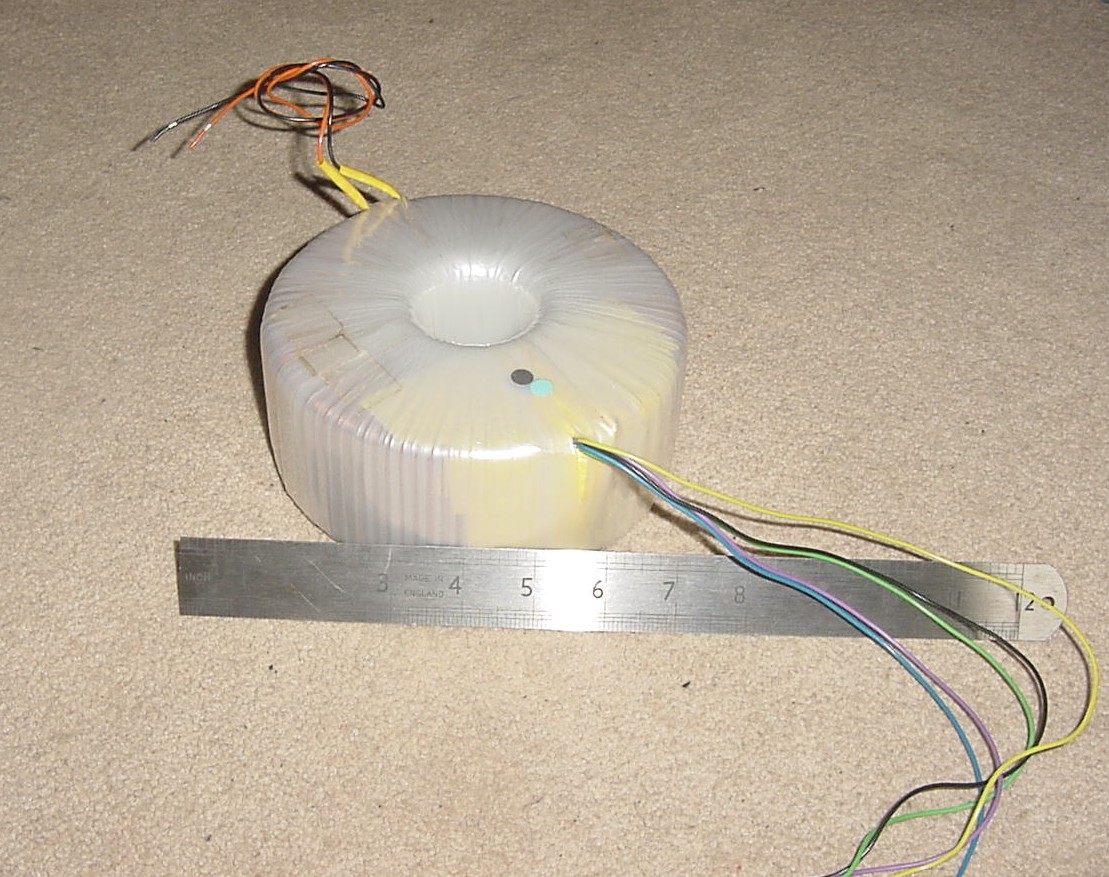

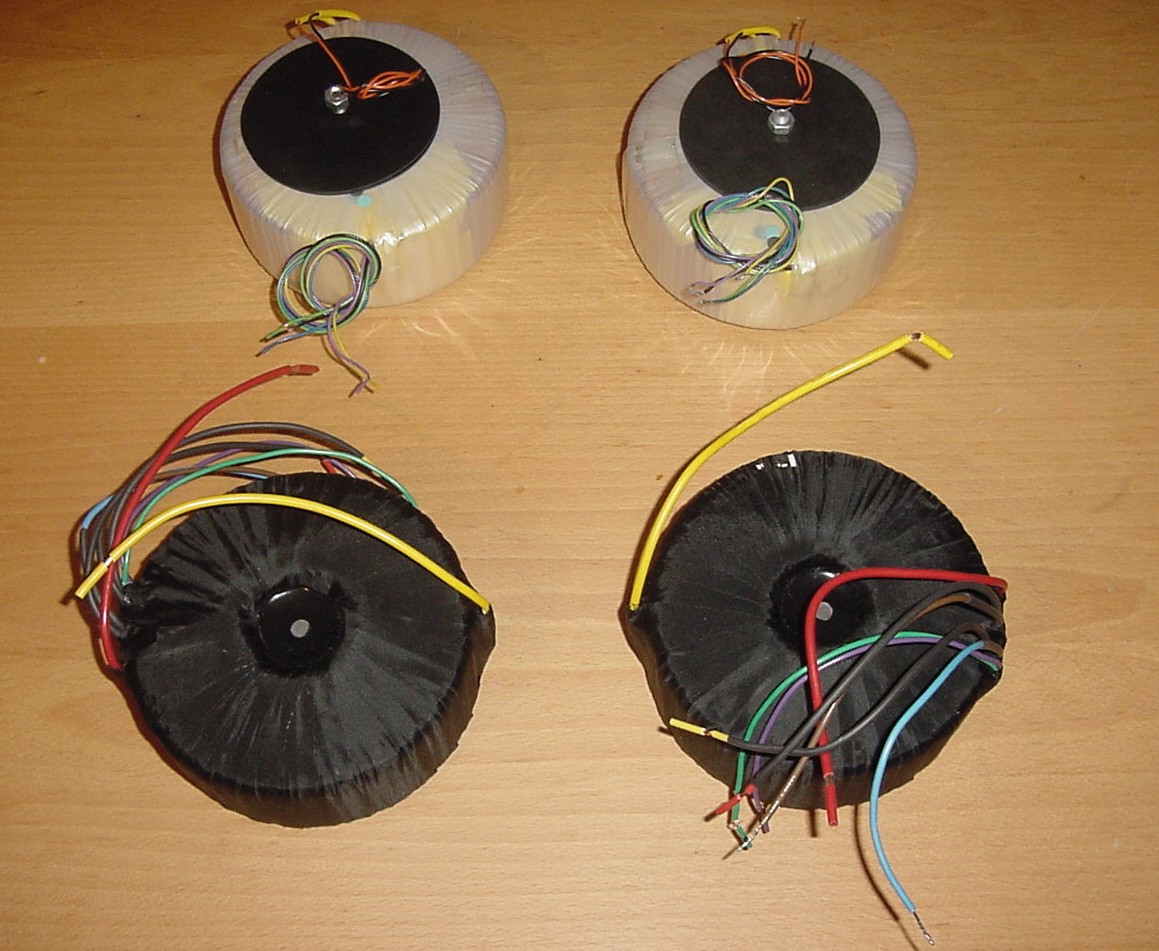

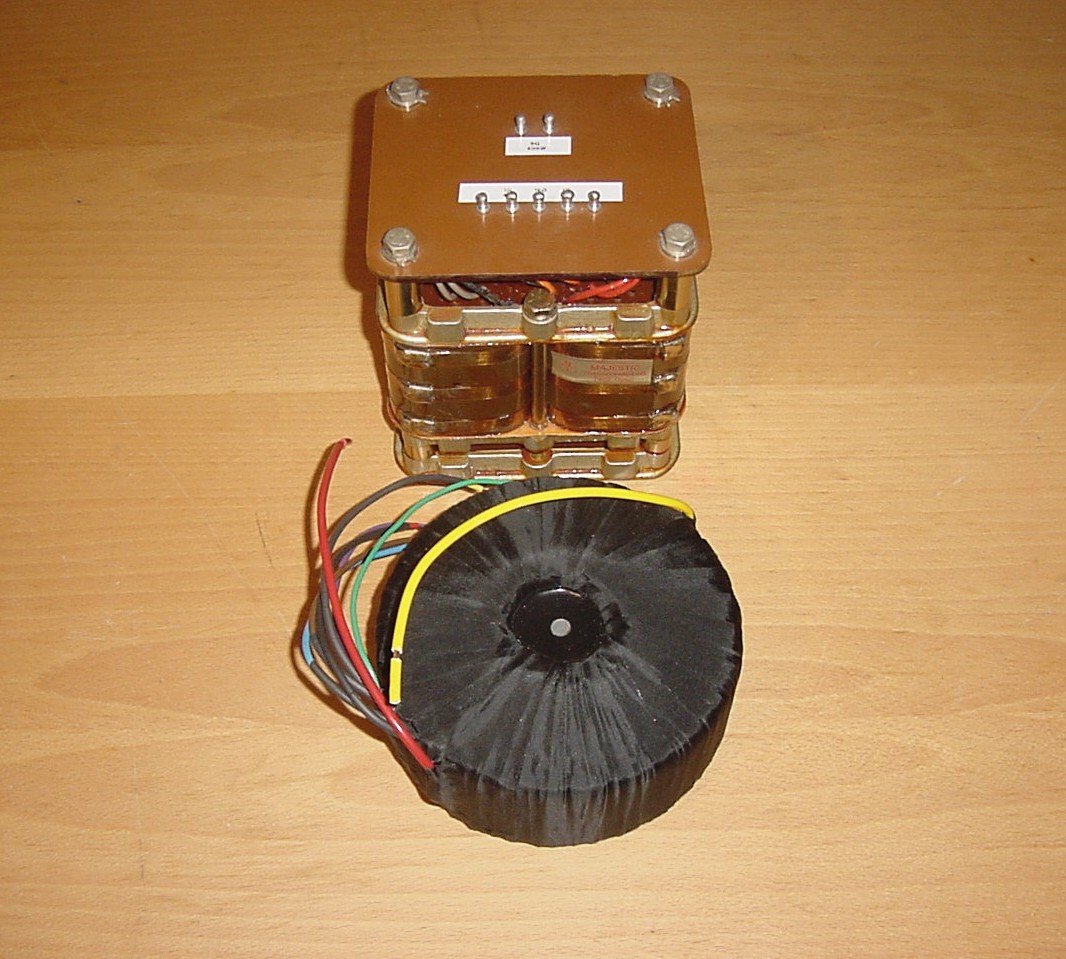

Two different types of output transformers are being offered a toroidal type and traditional open frame, both having been specially wound for the application

The Beam tetrode ultra linear output stage is preferable to the the pure tetrode or pentode connection for the following reasons -

Output impedance is much reduced from approximately 10k for tetrode and 1.2k for ultra linear.

Distortion in the output stage is is almost independent of changes load in impedance that occur in a loudspeaker system.

In a pure pentode connected amplifier using valves such as the EL34, distortion will consist of mostly odd order harmonics, for the KT88 in ultra linear connection distortion will consist of mostly even order harmonics, this distortion is cancelled out in the output transformer - or at least reduced and with the application of negative feedback distortion is further reduced to very low levels.

No additional screen supply is required resulting in higher efficiency.

Various types of KT88s will be tested the performance measured and the results will be published, there is a great deal of controversy regarding the merits of modern types of valves now available most of it ill informed and not based on measured results.

POWER SUPPLY

It has been decided that each channel of the amplifier will have its own separate dedicated power supply and mains transformer, benefits of this configuration are as follows

Crosstalk between channels will be kept to a minimum

Splitting the PSUs will half the current requirement for the heater supplies from 18 amps to a more manageable 9 amps per channel

The size required for each transformer will be just under 1000VA, which is far cheaper to get wound in the quantities we require

If 1 PSU were to fail the amplifier could continue to operate at reduced power (400w) on the other channel

The PSUs will have full power continuous rating* capable of delivering the total power output of the amplifier @ 800W RMS

* A full power continuous rating PSU means that the PSU is capable of supplying the maximum operating current at all times to both channels, enabling the amplifier to be driven at full power indefinitely (or until the output valves reach the end of their service life - 8000 to 10.000 hours)

Normally a commercial amplifier would not have such an over specified transformer/PSU and a 70% of full power rating would be more usual.

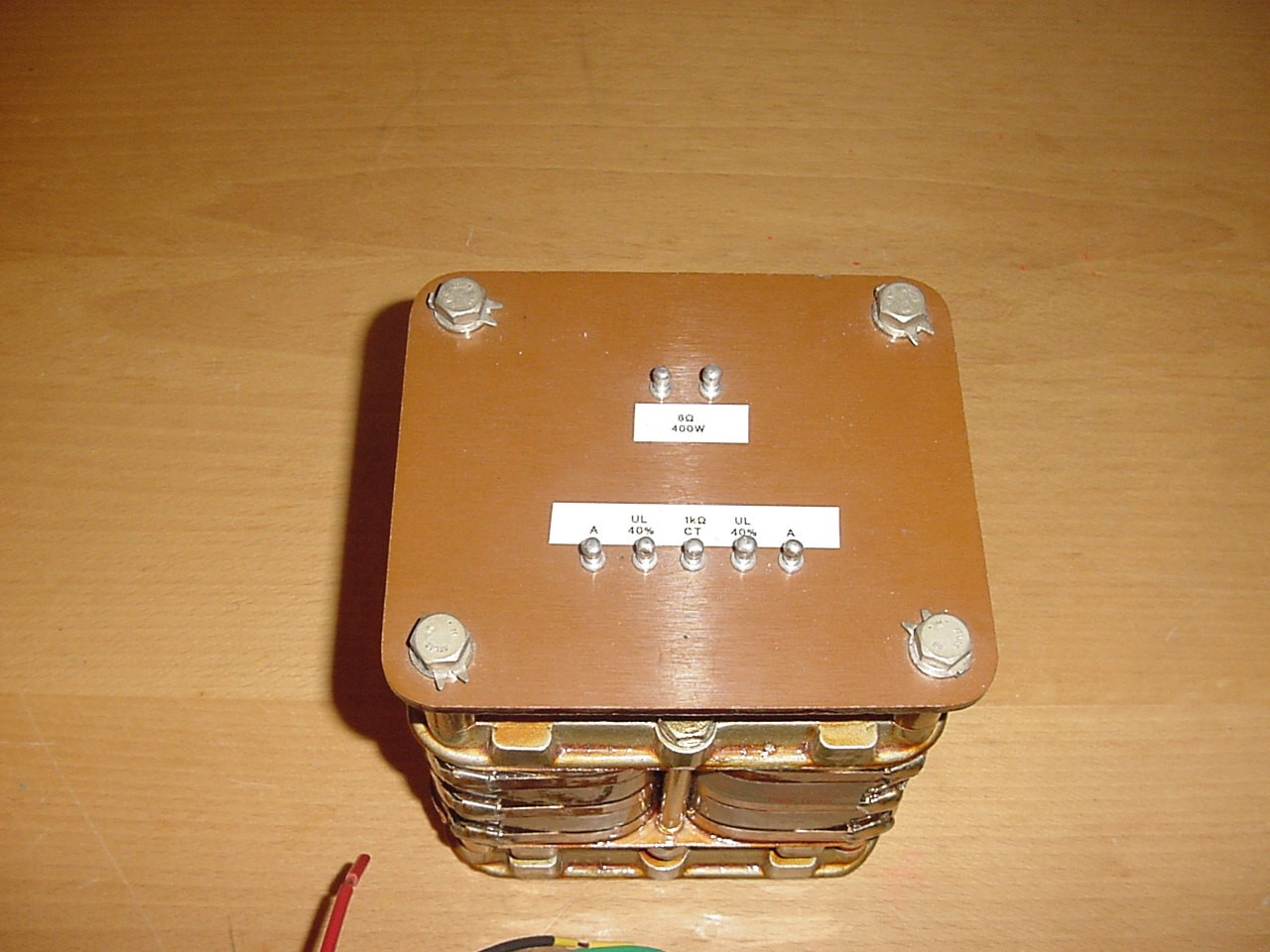

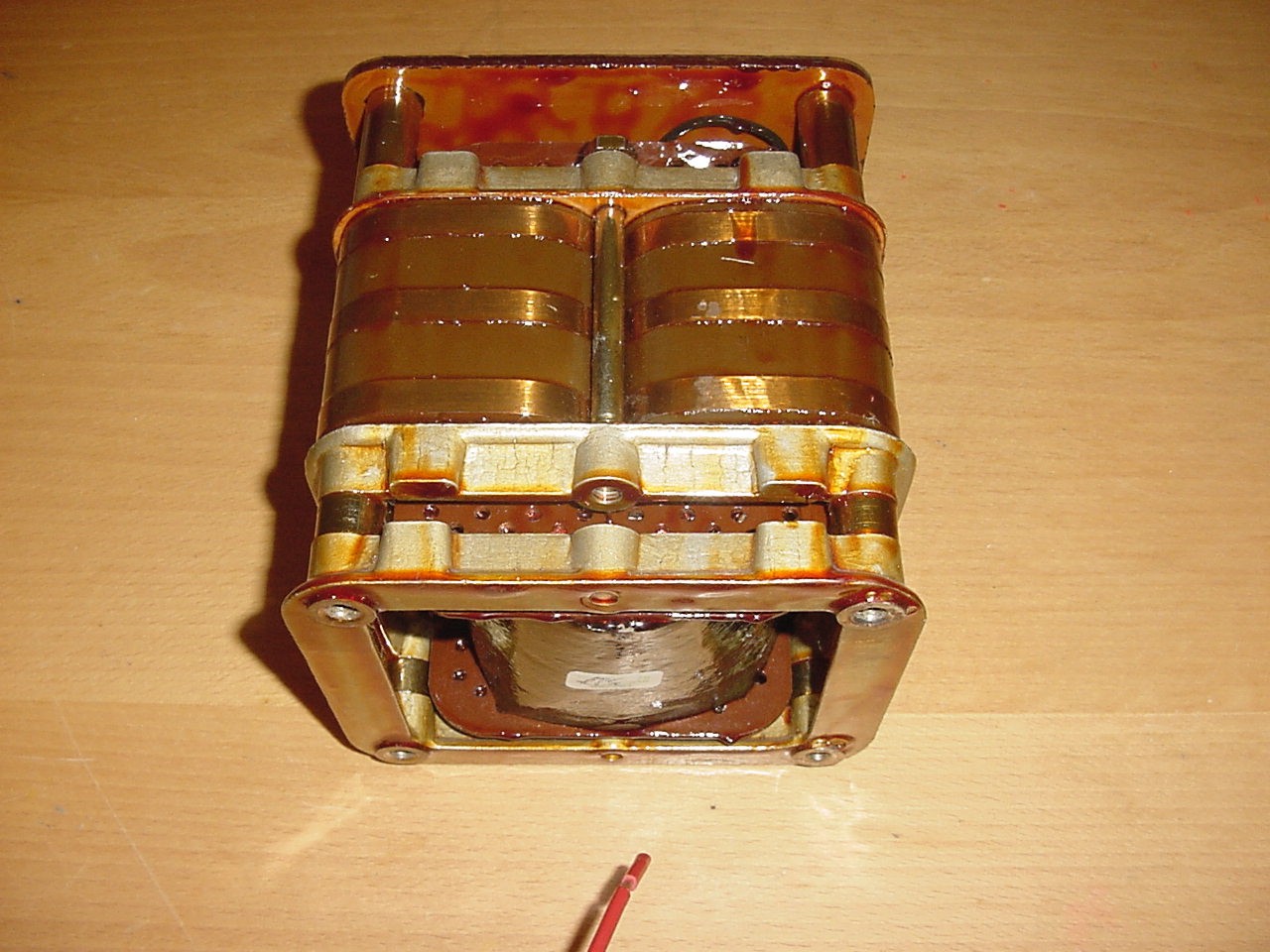

See above 2 X 400W RMS ultra linear output transformers and 2 X 1000VA power transformers for HT, Heaters and Grid bias

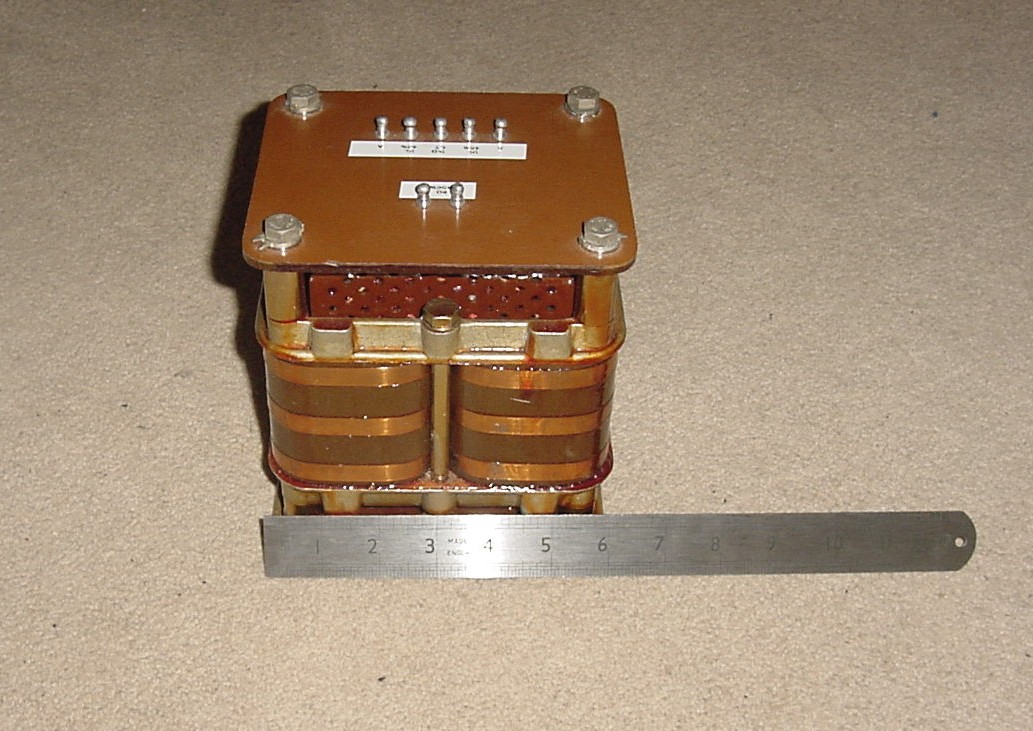

See above 1 X 400W RMS ultra linear output transformer (open frame) and 1 X 1000VA power transformer for HT, Heaters and Grid bias

Close ups of the open frame output Transformer Rated at 400W RMS

©2011 A&J AUDIO. All Rights Reserved.